Industrial Coating Equipment: Improved Surface Protection and Finishing Efficiency

Industrial coating equipment plays a vital role in the application of protective coatings, paints and finishing materials to surfaces in a variety of industries, including manufacturing and construction. From spray guns to powder coating systems, these tools provide precise and efficient coating application, enhancing durability, aesthetics and corrosion resistance. In this article, we'll look at the functions, features, and applications of industrial coating equipment, including spray guns, powder coating systems, and electrostatic paint applicators.

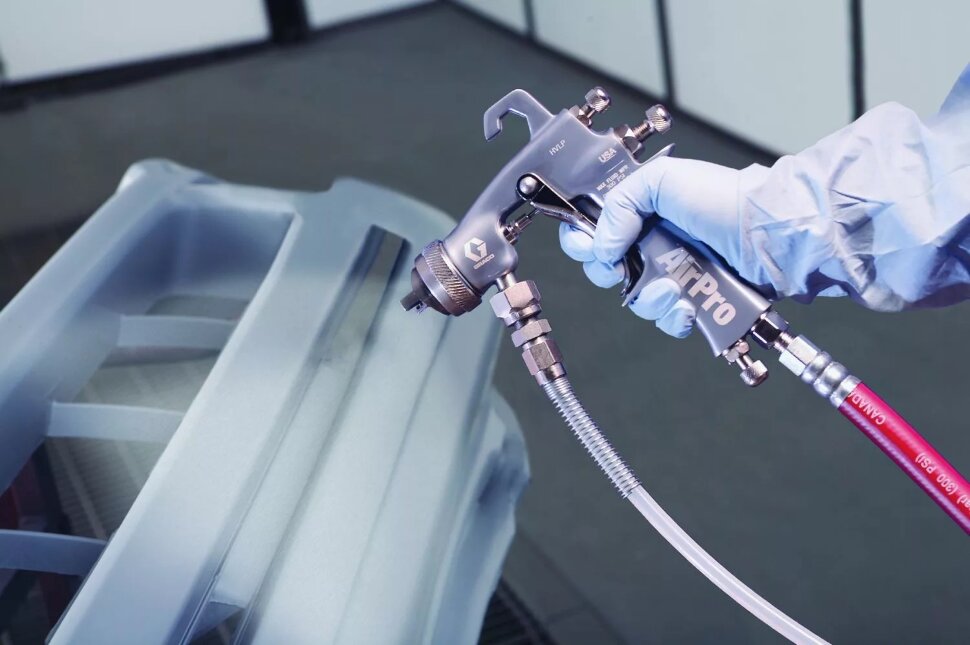

1. Spray Guns:

Spray guns are versatile tools used to apply liquid coatings such as paints, primers and sealants to surfaces. Key features and benefits of spray guns include:

- Precise Application: Spray guns allow precise control of coating thickness and coverage, ensuring uniform application and minimizing material waste.

- Versatility: Spray guns can be used with a wide range of paint materials, including solvent-based paints, water-based coatings and specialty finishes, making them suitable for a variety of applications and surfaces.

- High Transfer Efficiency: Today's spray guns provide high transfer efficiency by applying more coating material to the target surface and reducing overspray, resulting in reduced material consumption and cost savings.

- Easy to maintain: Spray guns are relatively easy to clean and maintain, and removable components and quick-disconnect features make routine maintenance easier and reduce downtime.

2. Powder coating systems:

Powder coating systems use electrostatically charged powder particles to create a durable, protective coating on metal surfaces. Key features and benefits of powder coating systems include:

- Eco-friendly: Powder coating is an environmentally friendly coating process that produces minimal amounts of volatile organic compounds (VOCs) and waste, making it a sustainable alternative to traditional liquid coatings.

- Enhanced Durability: Powder coatings provide superior resistance to corrosion, abrasion and chemical damage, resulting in a tough, durable finish suitable for harsh industrial environments.

- Effective Applications: Powder coating systems feature electrostatic spray guns that apply powder coatings evenly and efficiently, with high transfer efficiency and minimal overspray, reducing material waste and increasing productivity.

- Wide Color Range: Powder coatings are available in a wide range of colors, textures and finishes, offering versatility and customization to suit a variety of aesthetic and functional requirements.

3. Electrostatic Paint Applicators:

Electrostatic paint applicators use electrostatic attraction to ensure uniform coating and adhesion to conductive surfaces. Key features and benefits of electrostatic paint applicators include:

- Increased Transfer Efficiency: Electrostatic paint applicators charge paint particles with static electricity, causing them to be attracted to a grounded part, increasing transfer efficiency and reducing overspray.

- Even Coating Thickness: Electrostatic attraction ensures uniform coating thickness even on complex surfaces and hard-to-reach areas, minimizing the need for rework and touch-ups.

- Reduced Paint Consumption: Electrostatic paint requires less paint than conventional spray methods, resulting in reduced material consumption, cost savings and environmental impact.

- Improved Finish: Electrostatically applied coatings provide improved adhesion, finish quality and color consistency, resulting in superior surface appearance and performance.

Conclusion:

Industrial coating equipment including spray guns, powder coating systems and electrostatic paint applicators play a critical role in achieving durable, high-quality finishes and protecting surfaces in manufacturing and construction applications. By investing in advanced coating technologies and equipment tailored to their specific needs, industries can improve product aesthetics, durability and performance while optimizing efficiency, reducing waste and minimizing environmental impact. As industries continue to prioritize quality, efficiency and sustainability, the implementation of innovative coating solutions will play a key role in achieving operational excellence and meeting customer expectations in today's competitive marketplace.