In the busy world of manufacturing and logistics, efficiency is of the utmost importance. At the heart of streamlined operations are industrial conveyors and material handling systems. These systems, which include belt conveyors, roller conveyors and overhead conveyors, play a key role in the smooth transport of materials, components and products through the various stages of production and distribution. In this article, we'll take a closer look at each type of conveyor system, examining their features, applications, and contributions to the industrial landscape.

Belt Conveyors:

Features: Belt conveyors are the workhorses of material handling systems. These conveyors, consisting of a continuous cycle of material usually made of rubber or plastic, are driven by two or more pulleys. They can be flat or grooved and are easily adaptable to different production needs.

Application: Belt conveyors are used in a wide range of industries. From moving bulk materials such as grain, ore and aggregates to handling packaged goods and finished products, they are indispensable in manufacturing facilities, warehouses and distribution centers.

Benefits: Belt conveyors offer a number of advantages, including high productivity and efficiency, smooth and reliable operation, and the ability to transport materials over long distances over varying terrain. They can be customized to suit a variety of material types, shapes and sizes, making them versatile solutions for a variety of industrial environments.

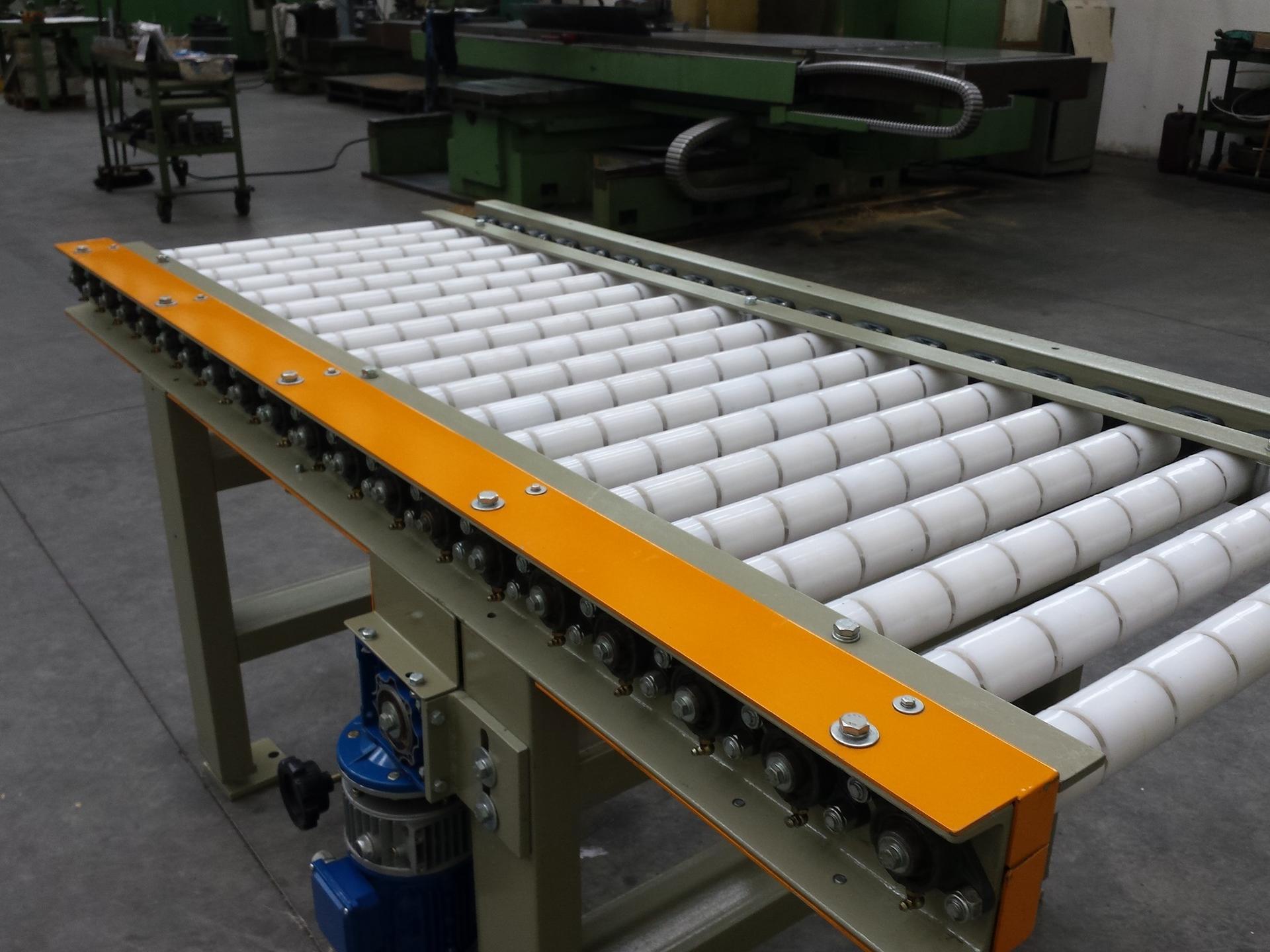

Roller Conveyors:

Features: Roller conveyors consist of a series of rollers mounted on a frame, which allows materials to be transported along a specified path. These conveyors can be powered by gravity or motors and are available in a variety of configurations, including straight, curved and spiral designs.

Application: Roller conveyors are commonly used to move cartons and pallets in warehouses, assembly lines, and shipping areas. They are ideal for applications requiring the accumulation, sorting and redistribution of products.

Benefits: Roller conveyors offer cost-effective, low-maintenance solutions for transporting heavy loads over short to medium distances. They provide smooth, quiet operation, ease of installation, and efficient product storage capabilities, improving workflow and productivity in industrial environments.

Overhead Conveyors:

Features: Overhead conveyors are installed above the production hall, suspended from the ceiling or overhead structure. They are equipped with holders or hooks that move along a track, transporting materials horizontally or vertically as needed.

Application: Overhead conveyors are used in a variety of applications including paint booths, assembly lines and finishing applications. They are especially useful in situations where floor space is limited or where products need to be transported through complex routes.

Benefits: Overhead conveyors maximize floor space, reduce clutter on the production floor, and provide efficient and ergonomic material handling solutions. They provide flexibility in routing and can easily handle irregularly shaped or delicate items, helping to improve efficiency and safety in industrial environments.

Conclusion:

Industrial conveyors and material handling systems are essential components of modern manufacturing and logistics operations. Whether it's belt conveyors for transporting bulk materials, roller conveyors for transporting cartons and pallets, or overhead conveyors for compact solutions, these systems play a vital role in optimizing workflow, increasing productivity and ensuring the smooth movement of materials and products throughout the supply chain. With their versatility, reliability and efficiency, industrial conveyors continue to drive innovation and efficiency in industrial plants around the world.