Title: Industrial Pumps: Essential Equipment for Fluid Control in Industry

Introduction: Industrial pumps are critical components used in a variety of industries to efficiently and reliably pump liquids in industrial processes, wastewater treatment and utility infrastructure. From centrifugal pumps to diaphragm and positive displacement pumps, these devices play a key role in maintaining fluid flow, pressure and circulation in a variety of industries. In this article, we will take a closer look at the functions, types, and applications of industrial pumps, highlighting their importance in modern industrial operations.

Functions of Industrial Pumps: Industrial pumps perform several important functions in industrial settings, including:

- Liquid Transfer: Pumps are used to move liquids, gases and slurries from one place to another as part of industrial processes, pipelines and storage tanks.

- Pressure Generation: Pumps generate pressure to overcome frictional losses and lift fluids to higher heights, allowing efficient distribution and delivery of fluids in industrial systems.

- Circulation: Pumps circulate process fluids through equipment and heat exchangers to facilitate cooling, heating, and chemical reactions in manufacturing processes.

- Wastewater Management: Industrial pumps play an important role in wastewater treatment plants for pumping wastewater, sludge and effluent during treatment processes such as filtration, sedimentation and disinfection.

- Utility infrastructure: Pumps are an integral part of the municipal infrastructure f

Types of industrial pumps:

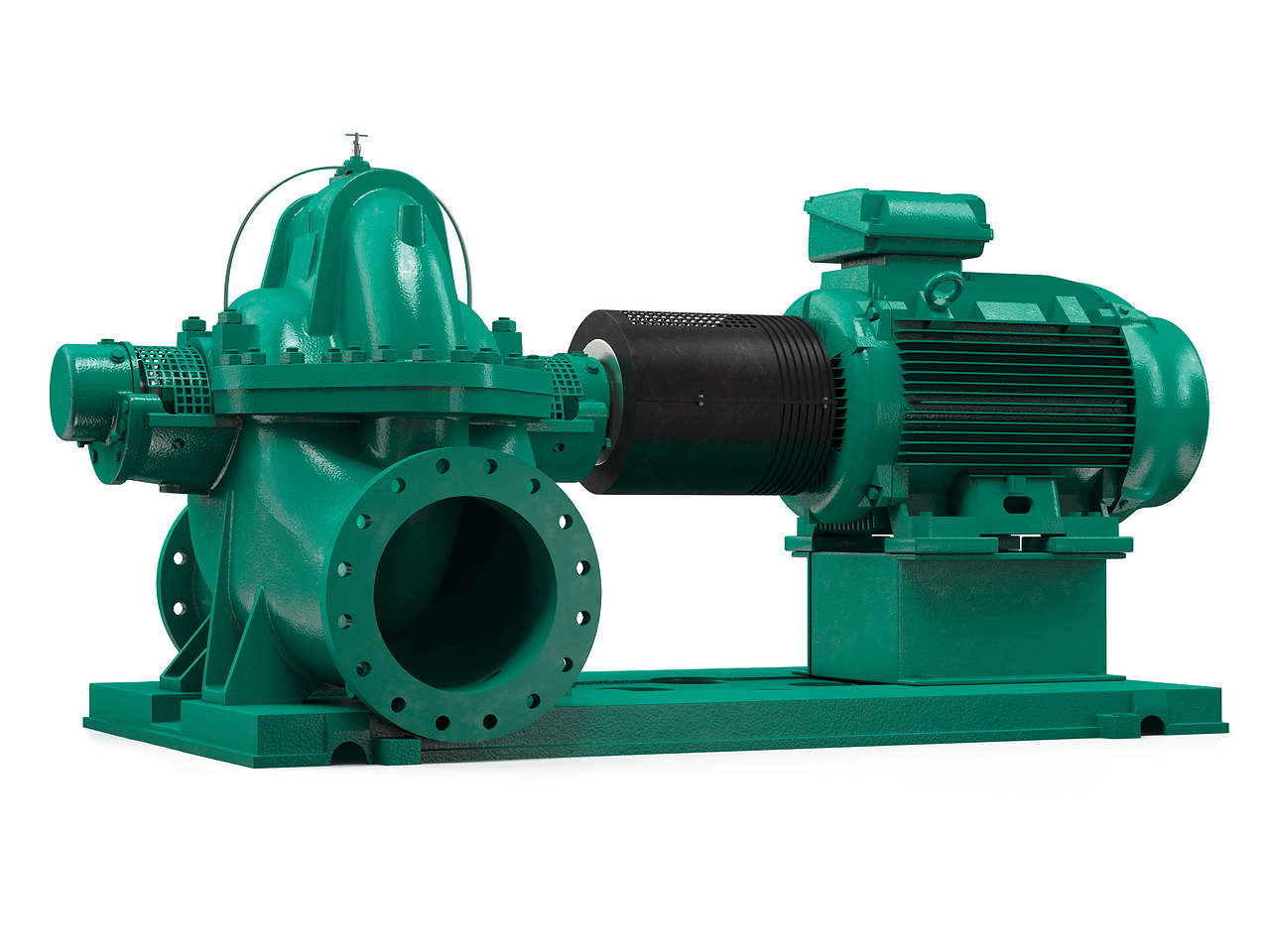

- Centrifugal Pumps: Centrifugal pumps use centrifugal force to transfer kinetic energy to fluids, creating a high-speed flow that is converted into pressure. These pumps are versatile and widely used in applications such as water transfer, chemical processing and air conditioning systems.

- Diaphragm pumps: Diameter

- Positive displacement pumps: Positive displacement pumps capture and move fluid by displacing a fixed volume f

- Submersible Pumps: Submersible pumps are designed to operate underwater in liquids typically used to pump groundwater, wastewater and sewage for municipal, industrial and agricultural purposes. These pumps are sealed to prevent damage to electrical components.

- Multistage Pumps: Multistage pumps consist of several impellers arranged in series to produce a high pressure fluid flow. These pumps are used for boiler feedwater, reverse osmosis, and high-pressure cleaning in industrial processes and utilities.

Industrial pump applications:

- Chemical Processing: Industrial pumps are used to pump, dispense and circulate chemicals in chemical plants, including acids, solvents and corrosive liquids.

- Oil and Gas: Pumps are essential for upstream, midstream and downstream operations in the oil and gas industry, including crude oil production, pipeline transportation and refinery processes.

- Water and wastewater treatment: Pumps play a critical role in water supply, distribution and wastewater management, including pumping raw water, treating wastewater, and transporting treated water for reuse or disposal.

- Manufacturing and Processing: Industrial pumps are used in manufacturing processes to transfer process fluids, lubricants, coolants and hydraulic fluids in machines, units and production lines.

- Utilities and Infrastructure: Pumps are an integral part of the utility infrastructure for water supply networks, fire suppression systems, irrigation systems and drainage systems in urban, rural and industrial settings.

Conclusion: Industrial pumps are essential fluid transfer equipment in a variety of industries, including centrifugal pumps, diaphragm pumps, positive displacement pumps, and specialized pump designs tailored to specific applications. By understanding the functions, types, and applications of industrial pumps, businesses can select the most appropriate pump technologies to optimize fluid transfer, improve operational efficiency, and ensure the reliable operation of their production processes, utility infrastructure, and environmental management systems.