Industrial Sensors and Instrumentation: Improving Control in Industrial Processes

In the field of industrial automation, sensors and instrumentation play a key role in monitoring and controlling critical parameters to ensure the efficiency, safety and reliability of industrial processes. From temperature and pressure sensors to flow and level sensors, these advanced technologies enable you to collect and analyze data in real time, making it easier to make informed decisions and optimize process performance. In this article, we delve into the world of industrial sensors and instrumentation, exploring their applications, functionality, and benefits in various industries.

1. Introduction to Industrial Sensors and Instrumentation:

Industrial sensors and instrumentation cover a wide range of devices designed to measure, monitor and control various physical parameters in industrial environments. These include temperature, pressure, flow, level, humidity, vibration and much more. By providing real-time data feedback, these sensors allow operators to monitor process conditions, detect anomalies, and take corrective actions to ensure optimal performance and safety.

2. Types of industrial sensors:

-

Temperature Sensors: Thermocouples, resistance temperature sensors (RTDs), and thermistors are commonly used to measure temperature in industrial processes, providing accurate and reliable temperature data for process control and monitoring.

-

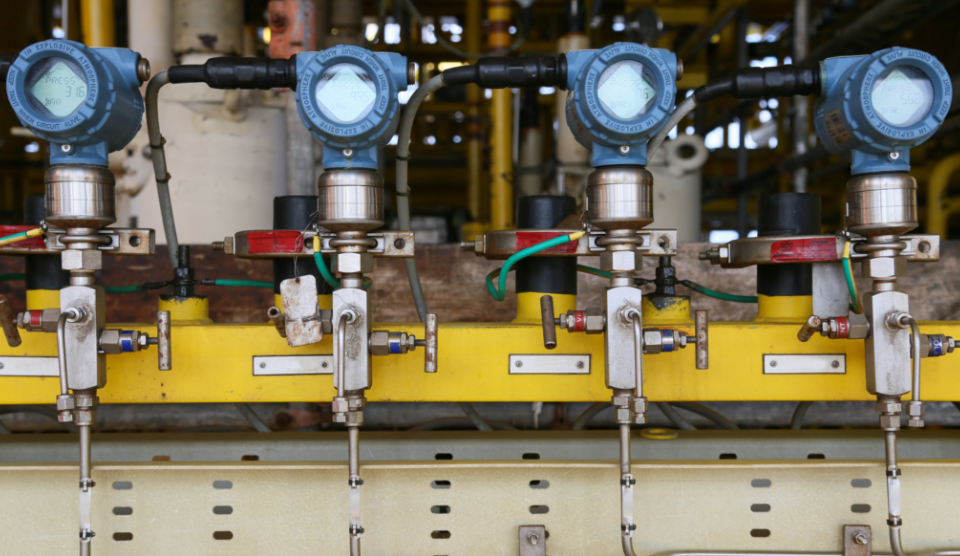

Pressure Sensors: Pressure sensors, pressure switches and pressure gauges are used to measure the pressure of a liquid or gas in a variety of industrial applications such as hydraulic systems, pneumatic systems and industrial equipment.

-

Flow Meters: Flow sensors and meters are used to measure the rate of fluid flow in pipelines and ducts, facilitating precise flow control and monitoring in industries such as oil and gas, water treatment and chemical processing.

-

Level Sensors: Level gauges, ultrasonic sensors and capacitive probes are used to measure the level of liquids, solids or granular materials in tanks, silos and vessels, providing precise inventory and process control.

-

Vibration Sensors: Accelerometers and vibration sensors are used to detect and monitor vibration levels in rotating machinery, motors and equipment, enabling predictive maintenance and early detection of equipment failures.

3. Applications of Industrial Sensors and Instrumentation:

-

Manufacturing: In the manufacturing industry, sensors and instrumentation are used to control quality, monitor processes, and monitor equipment condition. They provide real-time feedback on parameters such as temperature, pressure and vibration, ensuring product quality and operational efficiency.

-

Energy Management: Industrial sensors play a critical role in energy management systems by monitoring energy consumption, identifying energy inefficiencies and optimizing energy consumption in industrial facilities, promoting cost savings and sustainability.

-

Process Automation: Sensors and instrumentation are an integral part of process automation systems, allowing automated control of production processes based on real-time data feedback. This improves process efficiency, reduces manual intervention and improves overall productivity.

-

Safety and environmental monitoring: Industrial sensors are used to monitor safety and environment in explosive environments, detect gas leaks, fire hazards and environmental contaminants to ensure worker safety and meet regulatory requirements.{ 75}

4. Benefits of Industrial Sensors and Instrumentation:

-

Increased efficiency: By providing real-time data feedback, industrial sensors enable proactive decisions and process optimization, resulting in increased operational efficiency and productivity.

-

Enhanced Safety: Sensors and instrumentation play a critical role in keeping industrial processes safe by monitoring parameters such as temperature, pressure and vibration and detecting potential hazards or anomalies.

-

Reduced downtime: Early detection of equipment failures and predictive maintenance enabled by sensors help minimize unplanned downtime and production losses, resulting in increased equipment reliability and uptime.

-

Cost savings: Industrial sensors and instrumentation help save money by optimizing energy consumption, reducing waste and increasing process efficiency, resulting in lower operating costs and increased profitability.

5. Conclusion:

Industrial sensors and instrumentation are essential tools for monitoring and controlling critical parameters of industrial processes, ensuring efficiency, safety and reliability. From temperature and pressure sensors to flow and level sensors, these advanced technologies enable you to collect and analyze data in real time, making it easier to make informed decisions and optimize processes. As industries continue to evolve and demand for automation and control solutions increases, industrial sensors and instrumentation will continue to be essential to improve productivity, safety and sustainability across a variety of industries.