Industrial Shredders and Granulators: Revolutionizing Materials Processing and Waste Management

In today's world, effective waste management is not only a matter of environmental responsibility; it is also a critical aspect of resource conservation and sustainable development. Industrial shredders and granulators are at the forefront of this activity, playing a key role in the shredding and recycling of various materials such as plastic, paper and metal. In this article, we will delve into the world of industrial shredders and granulators, exploring their functions, applications, and contributions to the recycling and waste management industry.

1. Introduction to Industrial Shredders and Granulators:

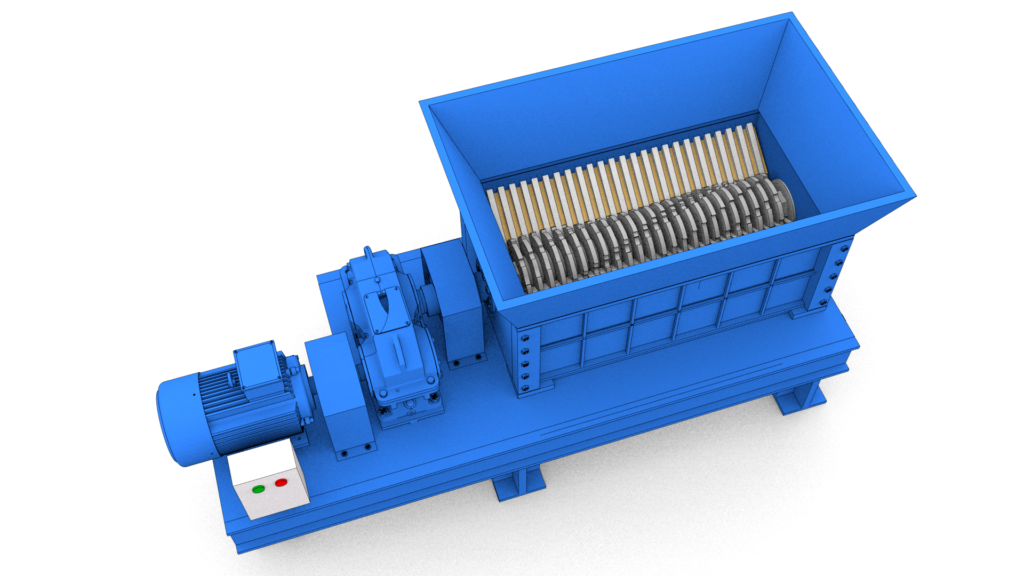

Industrial shredders and granulators are powerful machines designed to grind various materials into smaller particles or pieces. These machines are equipped with durable cutting mechanisms, such as rotating blades or hammers, that effectively shred materials, making them suitable for recycling or disposal.

2. Types of industrial shredders:

-

Single Shaft Shredders: These shredders feature a single rotating shaft with multiple blades or cutters that effectively shred materials into smaller pieces. They are typically used for processing bulky items such as plastic, wood and tires.

-

Twin Shaft Grinders: Twin shaft shredders use two counter-rotating shafts with interlocking blades to shred materials more efficiently. They are suitable for grinding harder materials and are often used in industrial processing plants.

-

Granulators: Granulators are machines that reduce materials into smaller particles or granules through cutting or grinding processes. They are widely used in the processing of plastic waste into reusable pellets for the production of new products.

3. Applications of industrial grinders and granulators:

-

Plastic Recycling: Industrial shredders and granulators are widely used in plastic recycling plants to process waste plastic into pellets or flakes. These recycled materials can then be used to make new plastic products.

-

Paper Shredding: Shredders are used in document shredding and paper recycling facilities to shred confidential documents, cardboard, and paper scraps into smaller pieces for recycling or safe disposal.

-

Metal Processing: Shredders and granulators are used in metal recycling facilities to shred and granulate scrap metal such as aluminum, copper and steel, making it easier to recover valuable metals for reuse.

4. Advantages of industrial grinders and granulators:

-

Waste Reduction: Industrial shredders and granulators help reduce waste by making it easier to handle, transport and recycle.

-

Resource Recovery: These machines recover valuable materials from waste streams, promoting resource conservation and circular economy principles.

-

Environmental Sustainability: By facilitating the recycling of materials and diverting waste from landfills, industrial shredders and granulators promote environmental sustainability and pollution prevention.

5. Conclusion:

Industrial shredders and granulators play a vital role in the recycling and waste management industry, ensuring the efficient processing of various materials for reuse or disposal. From plastic recycling to paper shredding to metal processing, these machines are essential tools for reducing waste, recovering valuable resources and promoting environmental sustainability. As the global focus on waste reduction and resource conservation continues to grow, industrial shredders and granulators will remain an important asset on the path to a greener future.